JP | EN

bearing/stainless steel/glass

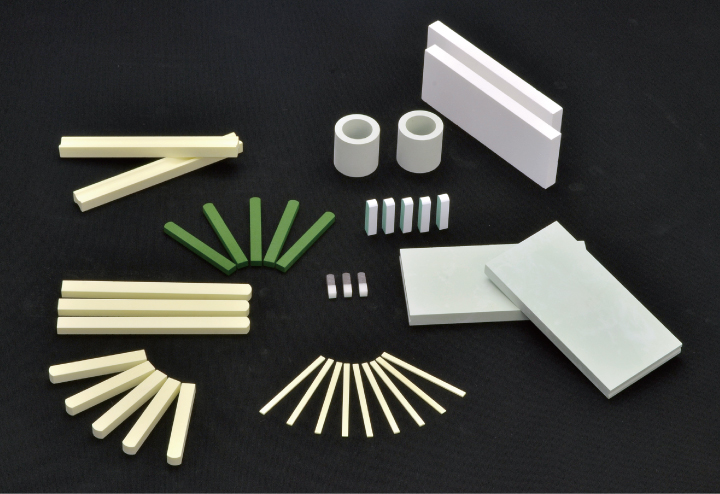

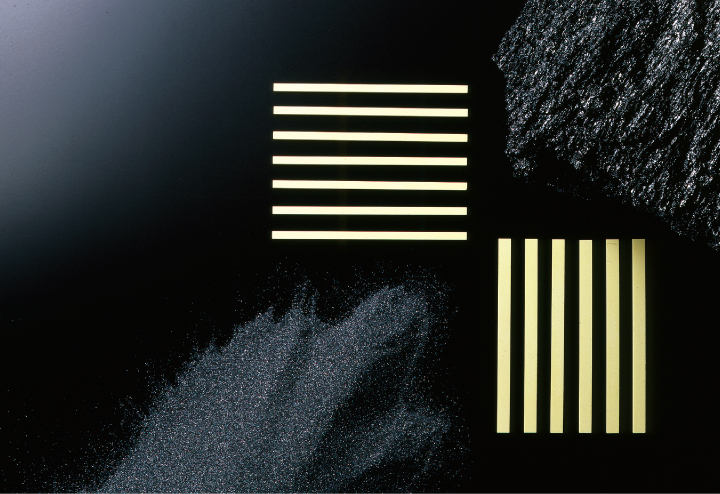

Variety and Characteristic of Super Finishing Stone

What is

Super Finishing Stone

Grindstone for polishing final stage of Metal product’ s surface.

By making the metal surface roughness fine, the surface will be less friction resistance, and less affected layer.

Suitable for every kind of Bearing’ s truck surface and for Needle Bearing’ s and Rollar

By making the metal surface roughness fine, the surface will be less friction resistance, and less affected layer.

Suitable for every kind of Bearing’ s truck surface and for Needle Bearing’ s and Rollar

Features and Advantages

of the Super Finishing Stone

1. The grit is chipped and comes off moderately when multidirectional oscillation is applied. As a result,the stone stays sharp longer and superior, constant performance is ensured.

2. Since the grindstone requires less pressure and slower speed than conventional tools,minimal heat is generated during the polishing process. Therefore, metal surface layer will not change.

3. The super finishing stones are user-friendly tools. Using stones with dedicated machine is a cost-effective way to grind a workpiece efficiently and accurately to very fine surfaces and contours.

Our engineers test our products using a variety of testing machines to suit your production needs.

2. Since the grindstone requires less pressure and slower speed than conventional tools,minimal heat is generated during the polishing process. Therefore, metal surface layer will not change.

3. The super finishing stones are user-friendly tools. Using stones with dedicated machine is a cost-effective way to grind a workpiece efficiently and accurately to very fine surfaces and contours.

Our engineers test our products using a variety of testing machines to suit your production needs.

Processing components and processing method

● What to process

Shaft / Cylindrical roller / Needle roller / Piston pin / Tapered Roller / Spherical Roller / Every kind of Bearings’ s truck surface

● How to process

Plunge Cut / Traverse Cut / In-feed processing / Through feed processing

Shaft / Cylindrical roller / Needle roller / Piston pin / Tapered Roller / Spherical Roller / Every kind of Bearings’ s truck surface

● How to process

Plunge Cut / Traverse Cut / In-feed processing / Through feed processing

Description of Super Finishing Stone

Description is as follows( for example) WA 3000( H3V2) RH35 2WA 6x6x100 3.5R

| Abrasive Grain | Grit | Bond | Hardness | Treatment | Size | Special Process |

|---|---|---|---|---|---|---|

| (example)WA | 3000 | (H3V2) | RH35 | 2WA | 6x6x100 | 3.5R |

Explanation for the description

| Abrasive Grain | We have many variety depending on the purpose. Please see details in below “Type and Specification of Abrasive Grain” |

|---|---|

| Grit | Conventional Grindstone #800~#6000. Superabrasive #800~more fine than #10000 |

| Bond | Encode the type of bond. Please ask us about the details. |

| Hardness | Rockwell Hardness (H) Scale number. Indicate within the range of RH(-)100~(+)130 |

| Treatment | What to impregnate. S/VS:Sulfur, 2WA:Wax |

| Dimension | Basically indicate with (Width)×(Thickness)×(Length). Regarding processing accuracy of each products, please ask us separately. |

| Special Process | Indication of how we processed after. |

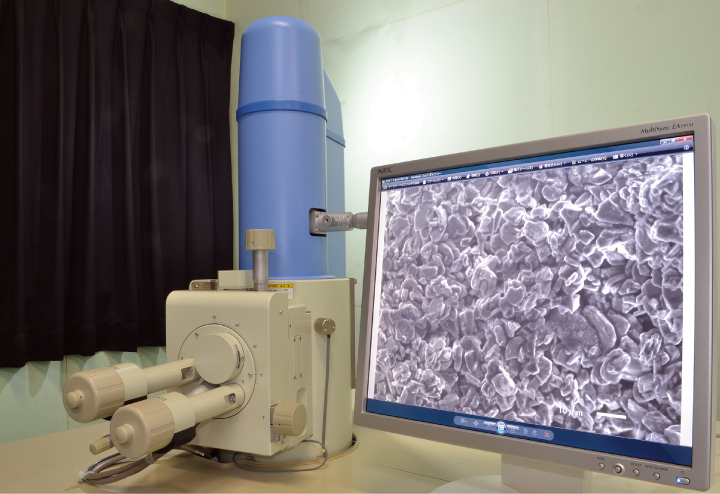

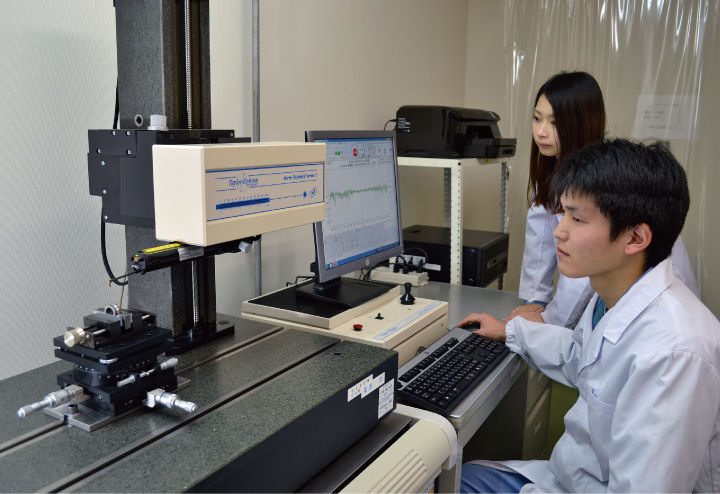

Testing facilities and evaluation

Our engineers test our products using a variety of testing machines to suit your production needs.

Testing our products by machines of B.P. drive system (SF-R-12S), 1 Shoe 2 Roller drive system(SF-S-11S) and measuring by surface roughness measuring machine “Form Talysurf TM S6” . We use these testing result and accumulated experience for making new products.

Testing our products by machines of B.P. drive system (SF-R-12S), 1 Shoe 2 Roller drive system(SF-S-11S) and measuring by surface roughness measuring machine “Form Talysurf TM S6” . We use these testing result and accumulated experience for making new products.

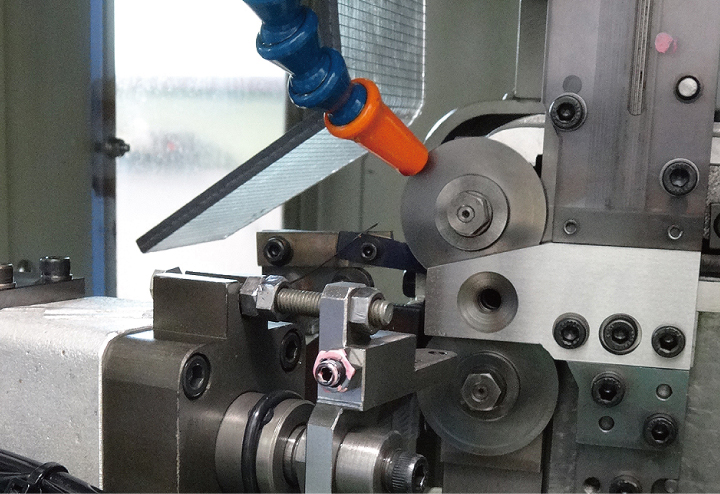

1 Shoe, 2 Roller drive system

Model:DAISEI SF-S-NS

B.P. drive system

Model:IZUMI KN-5323

Type and Specification of Abrasive Grain

For the customer who needs High Quality, Labor-saving, Cost Reduction and other requests,

we put in our effortfor each requests on a daily basis.

Regarding the selection of Grindstone, let us ask your condition of use. Please feel free to contact us.

we put in our effortfor each requests on a daily basis.

Regarding the selection of Grindstone, let us ask your condition of use. Please feel free to contact us.

| Abrasive Grain | Grit・Bond Code | Type | Sharpness | Life | Roughness | Characteristic |

|---|---|---|---|---|---|---|

| WA Aluminum Oxide |

800,1000 | Standard | excellent | Good polishing ability | ||

| 800,1000 | Hard | excellent | good | Longer life | ||

| 1200 | Standard | good | Good polishing ability | |||

| 1200(H3V1) | Hard | good | Longer life | |||

| 1200(H3V2) | Hard | excellent | good | More longer life | ||

| 1500(N3)、2000 | Standard | excellent | Good polishing ability | |||

| 2000(H3V1) | Hard | good | excellent | good | Satisfy both grinding ability and life | |

| 3000 | Standard | good | good | excellent | Well-balanced performance | |

| 3000(F-2) | Focused on polishing ability | good | Good grinding ability Good for small and middle size products |

|||

| 3000(F-4) | Focused on polishing ability | excellent | For difficult work material Good for Big products |

|||

| 3000(S-4) | Focused on roughness | good | excellent | Focused on surface roughness | ||

| 4000、5000、6000 | Standard | good | excellent | Focused on surface roughness | ||

| GC Silicon Carbide |

600、800、1000 | Standard | good | good | Well-balanced on polishing ability and roughness | |

| 2000(M1)、3000(M1) | Standard | good | good | Well-balanced on polishing ability and roughness | ||

| WA Aluminum Oxide + GC Silicon Carbide |

1200、1500、2000 | Standard | excellent | good | Good on polishing ability | |

| 2500(H3XQ) | Polishing ability, Life | good | good | good | Porous so well-balanced performance | |

| 3000A | Focused on polishing ability | excellent | Good polishing ability | |||

| 3000、4000 | Standard | good | good | excellent | Well-balanced on polishing ability and roughness | |

| 4000(JA) | Focused on polishing ability | excellent | good | Well-balanced on polishing ability and roughness | ||

| 5000(JAV1) | Focused on polishing ability | excellent | good | Well-balanced on polishing ability and roughness | ||

| SWG | 3000A | Focused on polishing ability | excellent | Good polishing ability | ||

| ZP Aluminum Oxide |

1500、2000、3000 4000、6000 |

Polishing ability, Life | excellent | excellent | Environment-responsive, Long life | |

| SB Aluminum Oxide |

1500(1386) | Hard | good | excellent | Longer life | |

| SSB | 2000 | Hard | good | excellent | good | Well-balanced on polishing ability and roughness |

| EP Aluminum Oxide |

1500、2000、4000 | Polishing ability, Life | good | excellent | Special for through feed | |

| 6000、8000 | Polishing ability, Life | good | excellent | excellent | Special for through feed | |

| Cr Chromium Oxide |

CR-10 | Roughness | good | excellent | Focused on surface roughness | |

| MSF Resinoid |

400、800、2000 | Life, Roughness | good | good | Touching softly to the work material | |

| F、S | Life, Rougness | good | excellent | Touching softly to the work material | ||

| CBN Cubic Boron Nitride |

2500、3500、5000 | Focused on roughness | excellent | excellent | Life is much longer | |

| 6000、8000、9000 | Focused on roughness | good | excellent | excellent | Longer life and good surface roughness |

Contact

Please feel free to contact us.