JP | EN

mechanic

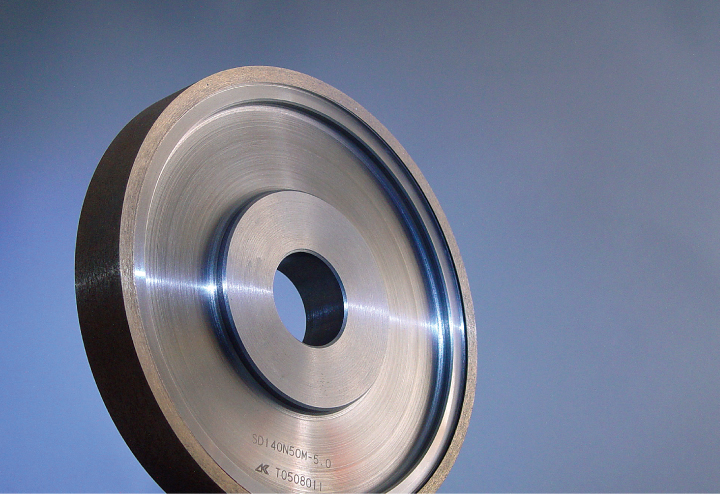

Diamond/CBN wheel

Features of super abrasive wheels

Diamond and CBN abrasives are known as “super-abrasives” in the world of machining.

They are several times harder than conventional abrasives, such as Sic and WA on Knoop hardness scales.

Since the very sharp-edged grit extends the tool life and boosts the performance of wheels, they are used for high precious wheels with high grindingratio.

The another advatage is the superior heat conductivity;13-20 times higher than that of Sic and WA, which enables them to absorb grinding heat and thereby prevent heat-induced deterioration of workpiece surfaces.

They are several times harder than conventional abrasives, such as Sic and WA on Knoop hardness scales.

Since the very sharp-edged grit extends the tool life and boosts the performance of wheels, they are used for high precious wheels with high grindingratio.

The another advatage is the superior heat conductivity;13-20 times higher than that of Sic and WA, which enables them to absorb grinding heat and thereby prevent heat-induced deterioration of workpiece surfaces.

Work materials

Diamond wheels ; Non-ferrous materials like hard alloy, ceramics, silicone, glass, concrete, polycrystalline sintered compact etc.

CBN wheels ; ferrous materials like carbon tool steel, high-speed steel, alloy tool steel, chrome steel,nickel chrome steel etc.

CBN wheels ; ferrous materials like carbon tool steel, high-speed steel, alloy tool steel, chrome steel,nickel chrome steel etc.

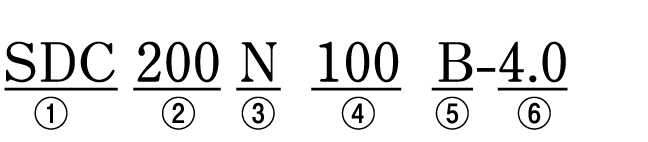

Specifications

①Type of abrasive grain

②Grit size

③Hardness

④Concentration

⑤Type of bond

⑥The thickness of abrasives

②Grit size

③Hardness

④Concentration

⑤Type of bond

⑥The thickness of abrasives

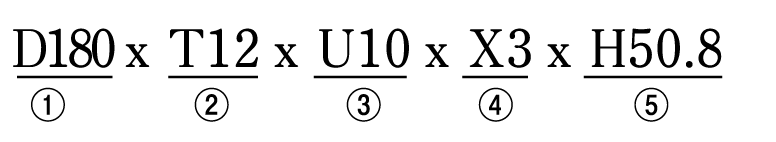

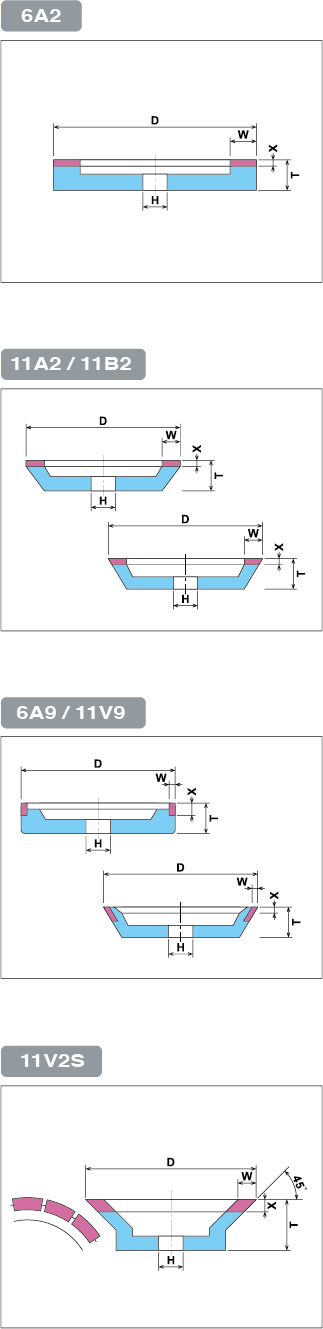

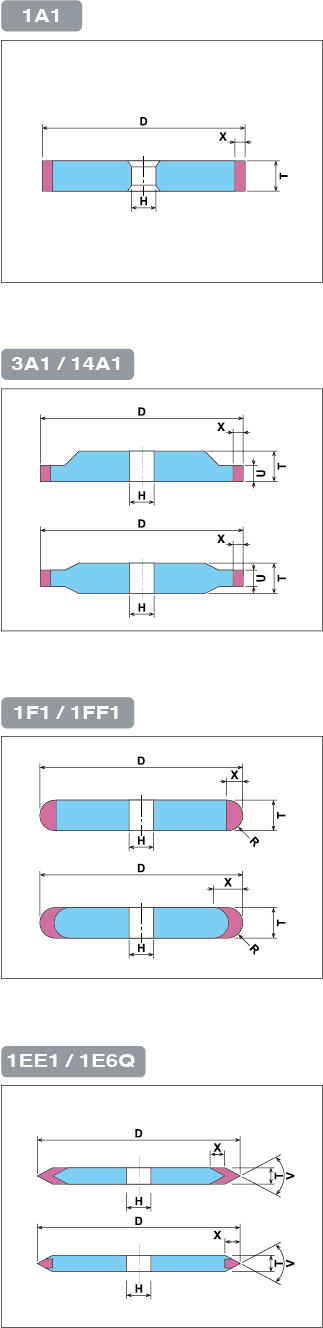

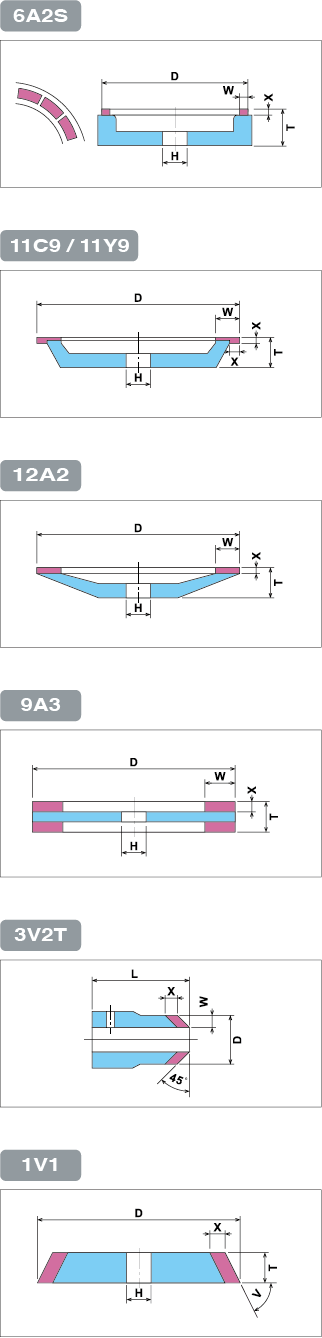

Dimensionning of the wheel

①D:outer diameter(mm)

②T:Body thickness(mm)

③U:Abrasive width(mm)

④X:Abrasive thickness(mm)

⑤H:Inner diameter(mm)

②T:Body thickness(mm)

③U:Abrasive width(mm)

④X:Abrasive thickness(mm)

⑤H:Inner diameter(mm)

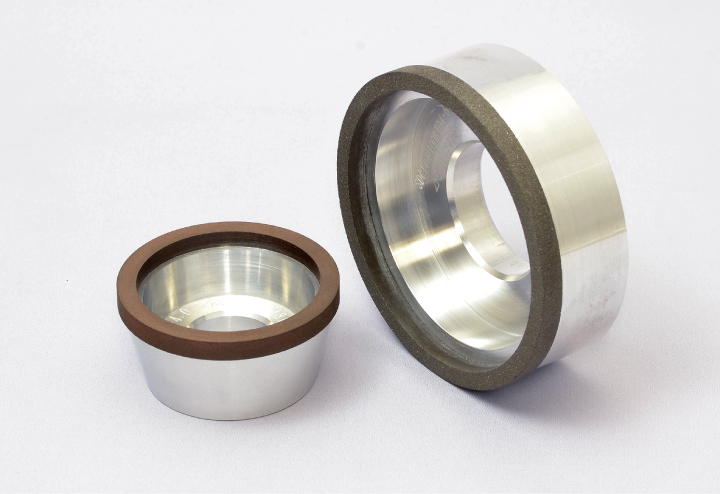

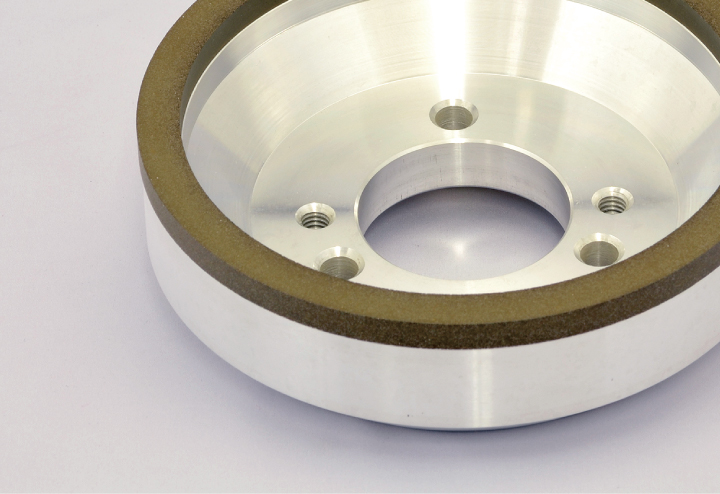

Standard shapes of Diamond wheels

Contact

Please feel free to contact us.